Heat loss and insulation heat loss from pipes tubes and tanks with and without insulation foam fiberglass rockwool and more.

Refrigerant pipe insulation thickness calculation.

Insulation thickness 77 7 mm.

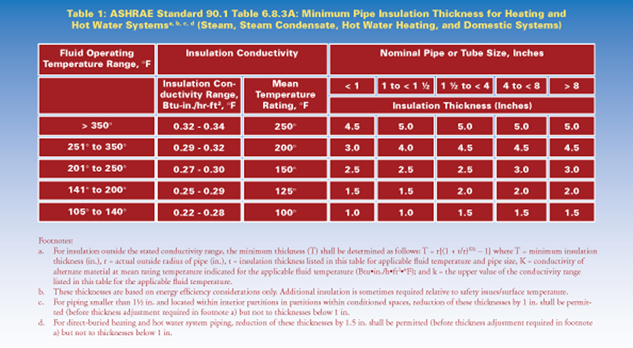

Pipe insulation thicknesses are greater than or equal to those in the 2007 standard but duct insulation thicknesses have not changed.

We have replicated the 2016 building energy efficiency standards table 120 3 a pipe insulation thickness below for this review which matches table c403 11 3 of the iecc international energy conservation code and ashrae 90 1 table 6 8 3 1.

Reduces mould and bacteria growth through microban antimicrobial product protection unique to armacell.

Insulation material complies with national construction code ncc fire tested for vertical pipe chases to nfpa274.

Armafix insulation pipe hangers easy to use insulated pipe hanger supports that protect against compression up to 1 wall thickness.

New pipe insulation thicknesses.

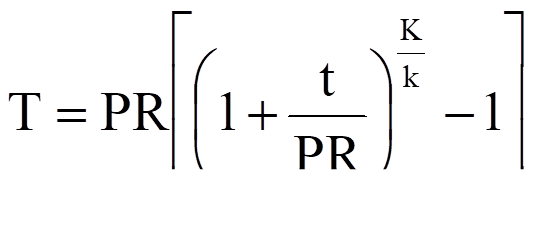

Extra margin must be taken on insulation thickness as sometimes conducting heat transfer through insulation may become higher than convective heat transfer due to air on outside wall of insulation.

In almost every scenario involving a heating pipe replacing 1 2 thickness pipe insulation with 1 thickness pipe insulation reduces the loss of heat transmission in half.

Piping and fittings for refrigerant vapor suction lines shall be insulated with insulation having a thermal resistivity of at least r 3 and having external surface permeance not exceeding 0 05 perm 2 87 ng s m 2 pa when tested in accordance with astm e 96.

Armacell fabricated fittings made to order pre fabricated fittings in tees elbows p traps and more.

Armaflex insulation tape black foam pressure sensitive seam tape.

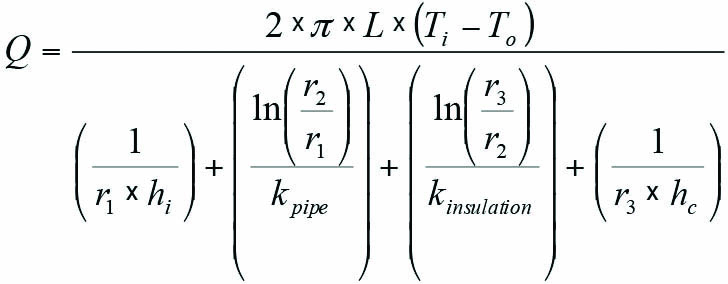

The heat loss from steam per meter of pipe length has to be.

What are the new pipe and duct insulation thickness requirements in standard 90 1 2010.

Calcium silicate insulation thermal conductivity of.

Decreases in both pressure and saturation temperature adversely affect compressor performance.

Thermal conductivity of the insulation material for the temperature range of the pipe can be taken as 0 04 w m k.

Hence insulation thickness ri rp 0 2302 0 1524 0 0777.

As refrigerant flows through pipes the pressure drops and changes the refrigerant saturation temperature.

Proper refrigeration system design attempts to minimize this change to less than 2 f 1 1 c per line.

Overall this is good news giving mechanical insulation an opportunity to contribute to.

Insulation heat transfer and heat loss from buildings and technical applications heat transfer coefficients and insulation methods and to reduce energy consumption.